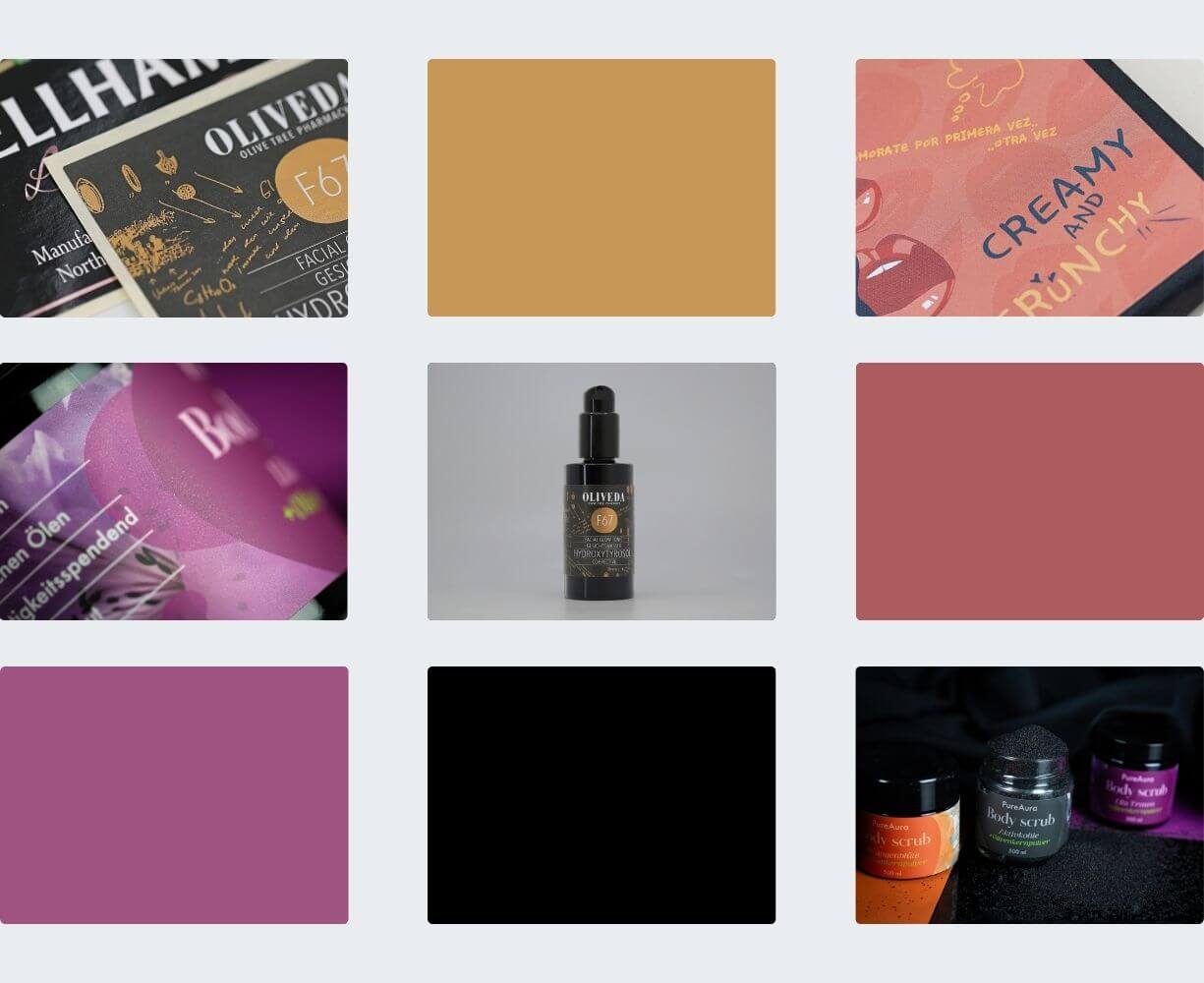

Extra protection for your labels: film lamination

Your labels deserve maximum durability and exceptional quality! Film lamination increases the strength of your labels, protects them from abrasion and thus makes them more durable. Especially for products that are frequently handled, film lamination is recommended. The dirt- and moisture-resistant film in matte or glossy is often used in the cosmetics, chemical and beverage industries. In addition, lamination gives your products a special appearance and thus enhances the advertising effect. So not only the appearance, but also the feel of your labels is positively influenced.

Film lamination emphasizes the high quality of your product and provides additional protection. In the online calculator, select the appropriate parameters, such as size, material and the desired film lamination. Then enter the remaining order details and upload the print files.

What is film lamination?

Film lamination involves covering printed materials such as paper or foil with a plastic film. At unieketiket.nl, film laminations are applied to the label using a procedure called wet lamination. This means that our film lamination is not self-adhesive, but is applied to the labels with liquid adhesive. Through printing, UV light and glue, the matte or glossy film is bonded to the label.

In addition, the film should be matched to the material: for a glossy material, a glossy film is suitable. If you choose a matte material, we recommend a matte film.

Do you need a design for your film laminated labels?

We take care of it! First, get inspired by our free sample book and gather ideas for the design of the labels with film lamination. Then our design service will guide you. A team of creative minds will work with you to develop the optimal design for your roll labels with film lamination. Choose the appropriate design package tailored to your needs. Our basic package includes print-ready data, unlimited usage rights and much more! Please note that the basic package includes the proof Basic. For labels with film lamination, you will need the Premium proof. Already have a design and just need the right printing data? Our artwork service will help you further and create or correct the printing data for you.

Film lamination or protective varnish!

Your label deserves extra protection! Here you have the choice between film lamination and protective varnish. As an alternative to our film lamination, which protects against wear, oil and moisture and makes your labels more robust, we offer matte or glossy protective varnish. Our protective varnish mostly provides protection against simple wear and tear. When applying protective varnish, a liquid lacquer is first applied to the surface of your labels, which later dries. We generally recommend protective varnish. For special requirements and irritations, film lamination is more suitable than protective lacquer. Since metallic labels are more sensitive to wear and tear, they should be film-laminated in any case.

Use our Premium proof to test the two refinements with protective function. If you choose the proof, we will produce a small quantity of labels with film lamination under original printing conditions. This way, you can be sure that the final result will fully meet your expectations.

Details of film lamination

Please note that protective lacquer is compatible with our finishes such as blind embossing or relief embossing, but film lamination cannot be combined with the aforementioned refinements. Moreover, labels with protective varnish can be printed afterwards in a thermal transfer printer, while film lamination is not suitable for this type of printing.

Materials and adhesives for labels with film lamination

In our online calculator you can choose from a variety of materials. Most coated materials are suitable for film lamination – natural or textured paper is not suitable. In addition to paper labels, film labels can also be provided with the special lamination. Moreover, we offer various sustainable solutions for your labels with extra protection.

Depending on where your film-laminated labels will be used, you will of course need the right adhesive. With us, you will find permanently adhesive labels, removable labels and freezer labels, among others. If you would like to see the materials and adhesive strength for your labels with film lamination in real life first, we recommend that you request our free sample book.

Try before you buy!

In our free sample book, you will find pre-cut labels that you can stick on your product as a sample. In addition, it contains different materials, numerous design ideas and various tips. Upon request, we will put together an individual sample package for you. Please feel free to contact us (+31) (0)30 808 05 97 or by e-mail: info@unieketiket.nl.

Embellished labels with unieketiket.nl: your options

If you choose labels with film lamination, there are even more finishing options. As explained earlier, film lamination and protective lacquer are refinements with a protective function. In addition, there are other decorative, traditional refinements: hot foil stamping, blind embossing and relief embossing. However, only hot foil stamping can be combined with film lamination. Our refinements at a glance? You can find more information on our overview page.

Digital refinements

Labels with digital spot varnish can also be provided with film lamination. This spot varnish is a transparent varnish that is applied to certain areas of the label to accentuate elements. The refinement is applied without special tools and therefore does not belong to the traditional refinements.

Production, shipping and further processing

Having labels printed with film lamination can be time-consuming. But it doesn’t have to be! The production time and delivery time are displayed directly in the online calculator at unieketiket.nl. In certain cases, you can opt for express production, which means you will receive your labels with extra protection even faster. Please note that the production time can be delayed by, for example, incorrect printing data or the production of die-cutting tools. In addition, we offer various shipping options.

After the production and delivery of your labels with film lamination, automatic, semi-automatic or manual labeling follows. Please note that during the ordering process for roll labels with film lamination, you must specify the correct winding direction so that you can successfully process them later.

What’s next?

On our overview page, you will find more information about the different refinements. In the online calculator, you can configure your individual labels with film lamination in just a few steps! If you do not find what you are looking for in the calculator, please contact us. We will be happy to help you further. Feel free to contact us at (+31) (0)30 808 05 97 or by e-mail: info@unieketiket.nl.

Useful tools and services

Proof

Want to make sure your printed labels look perfect? We print a proof of your label design on original machines and on the material of your choice.

Our free sample book

Are you looking for the right material for your labels? Order a free copy of our sample book and convince yourself of the quality of our printing!

Artwork service

We professionally prepare your print file(s) for you so that they meet all requirements for printing. Order one of our artwork services for this purpose!