Role configuration

What to consider when configuring labels on a roll

- Free in form & design

- Numerous formats

- High-quality digital printing

- Different winding directions

- Simple processing

- No shipping costs within the EU

Role configuration in a few steps

Roll labels are ideally suited for machine processing, that is, using a labeling machine to apply the labels to the product. Here it is important that you know the requirements of your machine used to apply the labels, so that you can order the right configuration for your roll labels. To do this, consult the instructions for the labeling machine or request the information from the processing company that will be applying the labels.

The following configuration elements may be of interest:

Roll diameter or number of labels per roll

Roll diameter indicates the size (diameter) of the rolls to be produced.

Specifying the maximum size of the roll is important so that it will fit into your labeling machine without problems during machine processing.

As for the size of the roll, you have a number of choices with us:

- You can also specify a maximum roll diameter. The largest size outside diameter you can order through the calculator is 350 mm. Larger diameters can also be produced on request.

- Or you can choose the desired number of labels per roll. To do this, during the 2nd step of the ordering process (“Order Information”), under the heading “Processing,” select the option “Apply with labeling machine,” and enter the required roll configuration.

- If you choose ‘Manual application of labels‘, the configuration is determined by us, we will produce and deliver the rolls as efficiently and ecologically as possible on standard roll core 76mm.

Roller core diameter

Our standard roll core diameter is 76 mm (inside diameter). For an additional charge, we can also supply at 40 mm and 25 mm. Ordering the correct size of roll core can be extremely important, especially if your labels will be processed by machine. Please refer to your labeling machine’s instructions for this. If your labels are applied manually, you do not need to choose the roll diameter, we always supply the standard roll core size 76 mm.

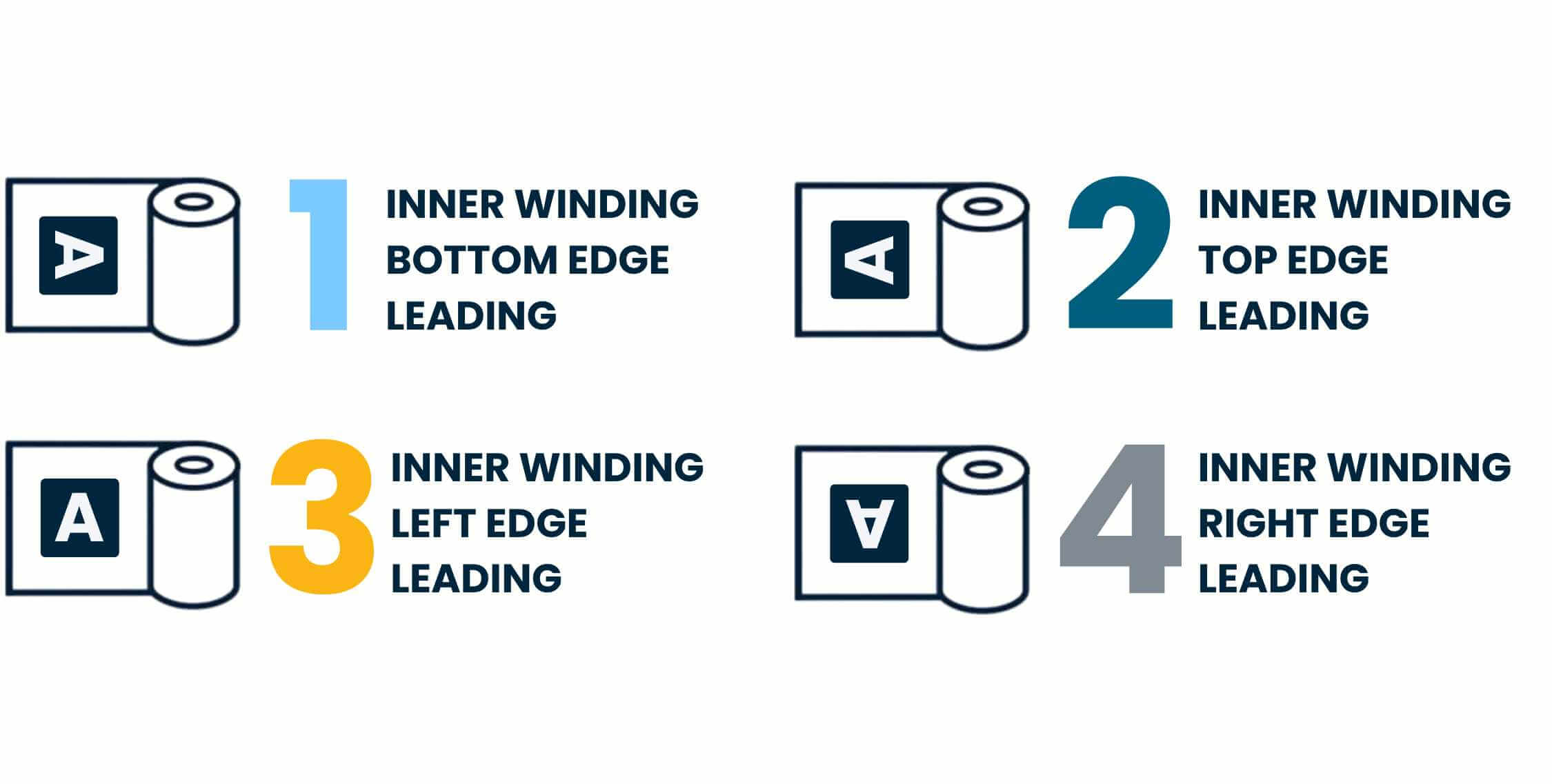

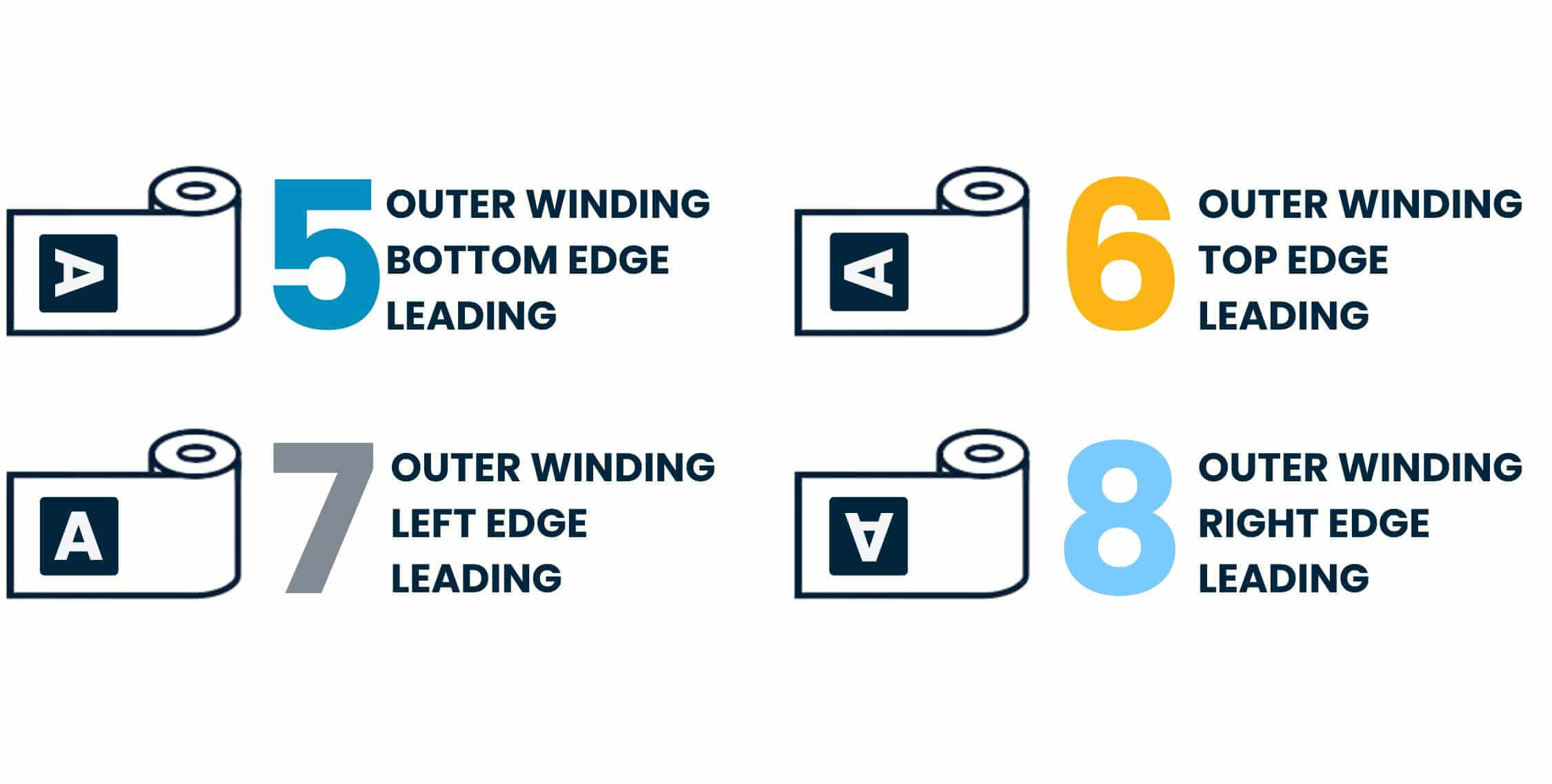

Winding direction

If the labels on roll are processed by machine, it is important to specify the correct winding direction when ordering. There are basically two types of roll wrapping for labels on rolls. Namely, printing on the INSIDE (inner winding) or printing on the OUTSIDE (outer winding).

Next, it is important to distinguish the positions of the labels on the roll. Thus, there are a total of four variants:

- bottom first

- top first

- left side first

- right side first

Label width and height

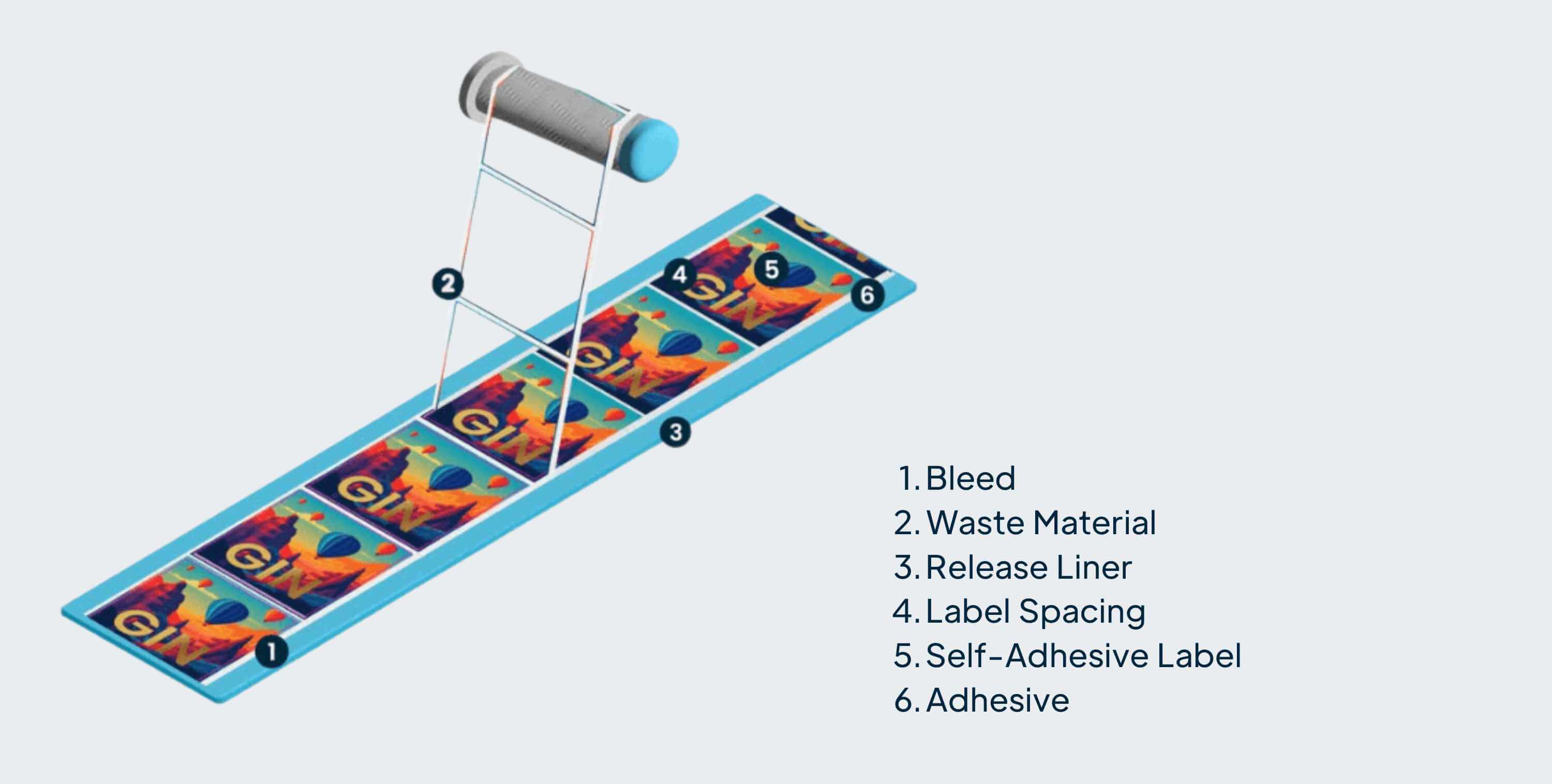

It is important to specify the final size of the label when ordering, i.e. without 2.5mm bleed all around. The width and height are defined based on the view of the label/design, i.e., “straight up,” as the label will later be placed on the product.

Example: if you need die-cut labels in size 50 x 100 mm (WxH), enter these dimensions in the calculator. In your print file, however, you must add a bleed of 2.5 mm all around. The size including the bleed will then be 55 x 105 mm.

Spacing of labels on roll

The “spacing” is the distance between two labels on the roll. As standard, we produce with 5 mm spacing between labels on the roll.

Upon request, we can supply labels on rolls with different spacing, however, always in whole millimeters. We recommend 3 mm as the minimum spacing. If the spacing is less than 3 mm, we can no longer remove the grid (the material surrounding the labels).

NB If you choose the “laser” die-cutting method, adjustment of the spacing is not possible.

Excess space of the carrier tape

The “excess space of carrier tape” of labels on roll, is the distance from the label edge to the edge of the roll. This space is found both above and below the labels on the roll.

By default, the excess space is 2.5 mm on each side. The roll width is therefore the size of the label (in width) on the roll + 5 mm.

Upon request, we can supply rolls with custom excess space of the carrier tape*. As minimum excess space we recommend 1.5 mm on both sides, total 3 mm. Larger excess spaces are possible upon request. Exceeding the minimum value may lead to problems with de-striping (removing the material lying around the labels).

NOTE If you choose die-cutting method ‘laser’, adjustment of the excess space is not possible.

The “excess space of the carrier tape” is irrelevant for labels on sheets.

Questions? You can reach us by telephone on (+31) (0)30 808 05 97 or by email: info@unieketiket.nl.